Product

Preview

Basic Info.Product Description

Basic Info.

| Place of Origin | JIA |

| Product name | Polyphenylen Oxide Ppo |

| Feature | High Temperature Resistance |

| Material | Polybutylene Terephthalate |

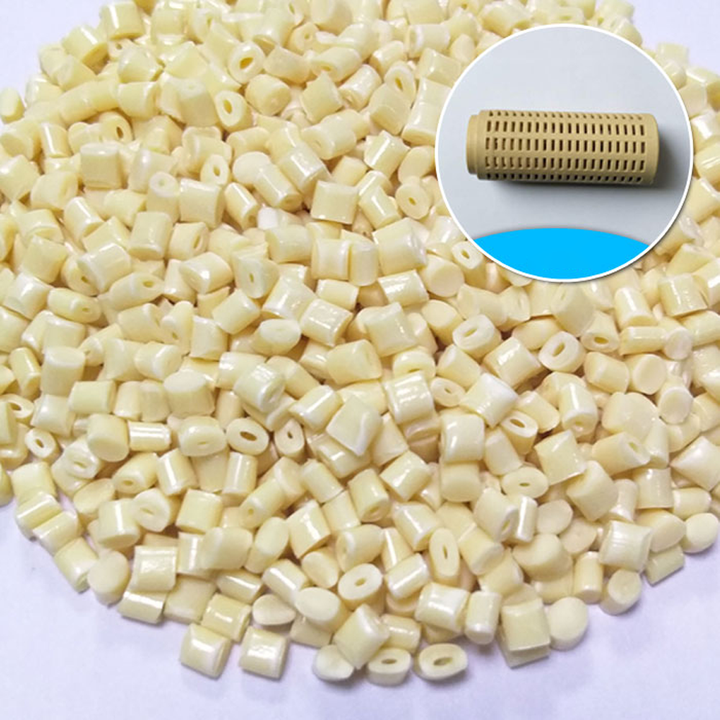

| Form | Plastic Pellets |

| Grade | Injection Grade |

| Place of Origin | China |

| Shape | Granular |

| Type | Vrigin |

| Quality | Off Grade |

| Color | Natural |

| Packaging Details | Carton Box & Wooden Box |

| Port | GuangZhou |

Product Description

Industrial PPO Resin PPE Material

PPO physical and chemical properties

PPO is one of the world's top five general engineering plastics. It has high rigidity and high heat resistance

It has the advantages of high combustion, high strength and excellent electrical properties. In addition, PPO also has the advantages of being green, north-facing, and resistant to pollution. The dielectric constant and dielectric loss of PPO are one of the smallest among engineering plastics and are almost unaffected by temperature and humidity. It can be used for low, medium and high frequency electrical power generation (the smaller the dielectric constant, the better the insulation). The load deformation temperature of PPO reaches more than 190°C and the degeneration temperature is -170°C.

PPO material properties:

1. It is white particles. It has good overall performance and can be used in 120-degree steam. It has good electrical insulation and low water absorption, but it has a tendency of stress cracking: modified polyphenylene ether can eliminate stress cracking.

2. It has outstanding electrical insulation, excellent water resistance and good dimensional stability.

3. MPPO is a modified material made by blending PPO and HIPS. All materials on the market are this kind of material.

4. It has high heat resistance, with a glass transition temperature of 211 degrees and a melting point of 268 degrees. It has a tendency to decompose when heated to 330 degrees. The higher the PPo content, the better the heat resistance, and the heat distortion temperature can reach 190 degrees.

5. It has good flame retardancy, is self-extinguishing, and has moderate flammability when mixed with HIPS. Light weight, non-toxic and can be used in the food and pharmaceutical industries.

It has poor light resistance and will change color if used in the sun for a long time.

6. Can be blended and modified with ABS, HDPE, PPS, PA, HIPS and glass fiber

PPO physical and chemical properties

PPO is one of the world's top five general engineering plastics. It has high rigidity and high heat resistance

It has the advantages of high combustion, high strength and excellent electrical properties. In addition, PPO also has the advantages of being green, north-facing, and resistant to pollution. The dielectric constant and dielectric loss of PPO are one of the smallest among engineering plastics and are almost unaffected by temperature and humidity. It can be used for low, medium and high frequency electrical power generation (the smaller the dielectric constant, the better the insulation). The load deformation temperature of PPO reaches more than 190°C and the degeneration temperature is -170°C.

PPO material properties:

1. It is white particles. It has good overall performance and can be used in 120-degree steam. It has good electrical insulation and low water absorption, but it has a tendency of stress cracking: modified polyphenylene ether can eliminate stress cracking.

2. It has outstanding electrical insulation, excellent water resistance and good dimensional stability.

3. MPPO is a modified material made by blending PPO and HIPS. All materials on the market are this kind of material.

4. It has high heat resistance, with a glass transition temperature of 211 degrees and a melting point of 268 degrees. It has a tendency to decompose when heated to 330 degrees. The higher the PPo content, the better the heat resistance, and the heat distortion temperature can reach 190 degrees.

5. It has good flame retardancy, is self-extinguishing, and has moderate flammability when mixed with HIPS. Light weight, non-toxic and can be used in the food and pharmaceutical industries.

It has poor light resistance and will change color if used in the sun for a long time.

6. Can be blended and modified with ABS, HDPE, PPS, PA, HIPS and glass fiber

PPE/PPO is a medium-high molecular weight polymer based on Polyphenylene Ether (PPE). This material is intended for use as an additive or a building block in a variety of thermoplastics and thermoplasticelastomers such as Styrenic Block Copolymers. PPE powder can be used to improve properties (i.e.HeatDistortion and Creep Resistance). It is hydrolytically stable and non-hydroscopic(typically less than 0.2% wateruptake). The polymer is soluble in common organic solvents like toluene, chloroform and THF . Chemical name: Poly (2,6-dimethyl-,1,4-phenylene ether)(PPE)Formula:(CH;O)n .

Company Profile

Aman Industry is a large-scale plastic industry and trade enterprise integrating new material research and development, plastic production, plastic import and export, and plastic trade. Mainly engaged in the production and sales of various plastic chemical raw materials.

AMAN company's main business: PPE PPO PBT PPS PVDF PEEK PA46PA12 PA6/66 POM PC TPU TPE EVA EAA and other engineering plastics. The raw materials are directly supplied by the manufacturer, with outstanding price advantages. The agent has a complete range of models and annual sales of tens of thousands of tons.

The corporate mission of Aman Industrial Plastics is: to be responsible to customers, employees, and society; to allow customers to cooperate sincerely, to allow employees to work with peace of mind, and to make the country feel at ease. To pursue the collective integration values of mutual benefit, mutual win, mutual help, mutual assistance and mutual unity.

The corporate vision of Aman Industrial Plastics is to use plastic import and export and plastic modified materials management as a platform to seek long-term, healthy and stable development of the enterprise, and to create higher and further value for the enterprise's customers, employees and even the whole society. , a trustworthy plasticizing company.

Aman Industry is a large-scale plastic industry and trade enterprise integrating new material research and development, plastic production, plastic import and export, and plastic trade. Mainly engaged in the production and sales of various plastic chemical raw materials.

AMAN company's main business: PPE PPO PBT PPS PVDF PEEK PA46PA12 PA6/66 POM PC TPU TPE EVA EAA and other engineering plastics. The raw materials are directly supplied by the manufacturer, with outstanding price advantages. The agent has a complete range of models and annual sales of tens of thousands of tons.

The corporate mission of Aman Industrial Plastics is: to be responsible to customers, employees, and society; to allow customers to cooperate sincerely, to allow employees to work with peace of mind, and to make the country feel at ease. To pursue the collective integration values of mutual benefit, mutual win, mutual help, mutual assistance and mutual unity.

The corporate vision of Aman Industrial Plastics is to use plastic import and export and plastic modified materials management as a platform to seek long-term, healthy and stable development of the enterprise, and to create higher and further value for the enterprise's customers, employees and even the whole society. , a trustworthy plasticizing company.

FAQ

Q: Are you trading company or manufacturer ?

A: We are trading company and manufacturer.

Q: Can you provide sample?

A: Sample is available, the freight collect.

Q: Can we customize the size of product?

A: Yes, our multiple CNC sawing capabilities allow us to manage larger sheet orders, producing repeatable, close-tolerance, cut-to-size sheet.

Q: What kinds of certificate you have?

A: Necessary test and certification can be obtained as you request.

Q: What is your MOQ?

A: From 1kg to FCL, we allow for maximum flexibility with minimum order quantities.

Q: How about your deliver time?

A: It generally needs about 3-15 days, also depends on the quantity.

Q: Are you trading company or manufacturer ?

A: We are trading company and manufacturer.

Q: Can you provide sample?

A: Sample is available, the freight collect.

Q: Can we customize the size of product?

A: Yes, our multiple CNC sawing capabilities allow us to manage larger sheet orders, producing repeatable, close-tolerance, cut-to-size sheet.

Q: What kinds of certificate you have?

A: Necessary test and certification can be obtained as you request.

Q: What is your MOQ?

A: From 1kg to FCL, we allow for maximum flexibility with minimum order quantities.

Q: How about your deliver time?

A: It generally needs about 3-15 days, also depends on the quantity.

Polyphenylene Oxide PPO PPE Plastic Raw Material For Base Station

$4

Smart Device Industry Chain · Material · Rubber and Plastics

Wuxi

Wuxi  Authenticated

Authenticated