Product

Preview

Basic Info.Product Description

Basic Info.

| Place of Origin | Hebei, China |

| Brand Name | LINYI |

| Grade | spray coating, calendering, rotational molding grade, hollow grade, molding, M10, M7.5, M15, B, Other, M40, M25, M12.5, A, M30, M3, M5 (bedding), M20, C, foaming grade, hot melt grade, blow molding grade, extrusion grade, blown film grade, injection molding grade, demoulding grade, coating grade, drawing grade, Other |

| Feature | Flame retardant grade, Chemical Resistance, weather resistance, High crystallinity (HCPP), wear resistance, low temperature resistance, High flow, toughened grade, High impact resistance, High sliding, standard grade, hydrolysis resistance, High Strength, transparent grade, High Rigidity, conductive grade, High Gloss, ANTISTATIC, Powder, reinforced grade, high temperature resistance, aging resistance, UV resistance |

| Application | automotive parts, optical grade, pipe grade, sports equipment, medical grade, special materials for cast films Materials, home appliance components, fibers, plate grade, electronic and electrical components, profiles, wire and cable grades, thin-walled products, film grade, special materials for bottle caps, power tool accessories, lighting fixtures, filling grade, General grade |

| color | White |

| Shape | White loose columnar solid |

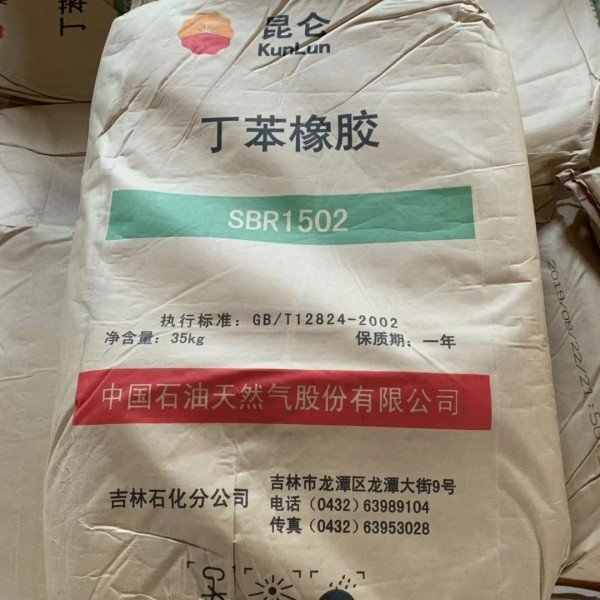

| Product name | Polymerized Styrene Butadiene Rubber |

| Other Name | SBR,Styrene, 1,3-butadiene polymer |

| CAS NO. | 9003-55-8 |

| MF | C12H14 |

| MW | 158.243 |

| Certification | ISO |

| Application | For tires, tapes, hoses, wires and cables, etc. |

| Sample | Free |

| Package | 25 kg/bag,customized packaging. |

| Storage | Store in a cool, dry place |

| Selling Units: | Single item |

| Single package size: | 110X110X120 cm |

| Single gross weight: | 25.100 kg |

Product Description

Preview

Main Products

Preview

Preview

Preview

Preview

Titanium dioxide Ethylene Propylene Rubber EPM Zinc Oxide Silicone rubber

Product Description

Styrene Butadiene Rubber (SBR)Styrene Butadiene Rubber (SBR) is the abbreviation of Polymerized Styrene Butadiene Rubber. Styrene Butadiene Rubber is the backbone of the rubber industry, is the largest general-purpose synthetic rubber varieties, but also one of the earliest industrialized production of synthetic rubber varieties.

Preview

According to the polymerization process, SBR is divided into emulsion styrene butadiene rubber (ESBR) and solution styrene butadiene rubber (SSBR). Compared with the solubilized SBR process, the emulsion SBR process is more advantageous in terms of cost savings, and about 75% of the global SBR plant capacity is based on the emulsion SBR process. Emulsion SBR has good overall performance, mature process, widely used, capacity, production and consumption in the first place in the SBR. Oil-filled styrene butadiene rubber has the advantages of good processing performance, low heat generation, good low-temperature flexibility, etc. It has excellent traction performance and abrasion resistance when used for tread rubber, and the plasticity of the rubber is enhanced after oil-filling, which is easy to mix, and at the same time, it can reduce the cost and improve the production.

Preview

Preview

Preview

Preview

Preview

Preview

Specification

Application

Styrene butadiene rubber (SBR), also known as polystyrene-butadiene copolymer. Its physical properties, processing performance and product performance is close to natural rubber, some properties such as abrasion resistance, heat resistance, aging resistance and vulcanization speed is more excellent than natural rubber, can be used with natural rubber and a variety of synthetic rubber, widely used in tires, tapes, hoses, wires and cables, medical equipment and the production of a variety of rubber products and other fields, it is the largest general-purpose synthetic rubber varieties.

Preview

Packing & Delivery

Preview

Preview

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

Preview

Preview

Preview

Preview

Preview

Preview

Preview

Hebei Linyi New Material Technology Co., Ltd. is located in Hebei, our products have a competitive advantage in the market. We have long-term cooperation with key domestic development enterprises such as Luoyang Institute of Refractories Research,Anshan Jiaohua Refractory Design & Research Institute,Kunlun Petrochemical, Sinopec, Zhongtai Group, Non-ferrous Metal Mining (Group), Junzheng Group and Longbai Group. Our products include refractory bricks, refractory coatings, refractory plates, PVC resins, PVC additives, chemical additives, etc. Over the years, our company has been striving to achieve good quality and low prices, which has won the support and trust of many customers. We look forward to working with you and establishing a win-win relationship with you. Please rest assured that we will make you happy.Back Home

Exhibition and customers visit factory

Preview

Preview

Preview

Preview

Preview

Preview

Certifications

Preview

FAQ

▲Q:What is your packing? A: The products are usually packaged in bags, cartons and drums. Product packaging varies according to the product.We accept custom packaging. ▲Q:What is the delivery time? A: Products are in stock. Shipping time depends on the type and quantity of the product. About 7-15 days.▲Q:What is the payment terms? A: TT or spot letter of credit. The payment method is determined by negotiation. ▲Q:What is your transport? A: Normally by sea ,by truck or by Rail;Urgently by air . ▲ Q:Can I get the sample before placing the order? A: Of course,we can provide samples for your test.You just need to tell us the address and the quantity of samples you need. ▲Q:Can you give me a discount? A: Of course, we will offer you the best discount according to the quantity of your order.▲Q:Where is your shipping port? A: Tianjin port,Qingdao port,Ningbo port and Shanghai port.

If you are interested in our product,please contact us.

Thermoplastic Polymerized Styrene Butadiene Rubber SBR

$900 ~ $1200

Smart Device Industry Chain · Material · Rubber and Plastics

Chengde

Chengde  Authenticated

Authenticated50-99 EmployeesInformation Services and IT