Product

Preview

Basic Info.Product Description

Basic Info.

| Grade | FIRST-CLASS |

| Feature | High Strength, high temperature resistance, Chemical Resistance, High Rigidity, High sliding |

| Application | WAREHOUSE, Cabinet door panel design, Food Grade, special materials for bottle caps, Cabinet door panel design, WAREHOUSE, Cabinet door panel design, WAREHOUSE, Cabinet door panel design, WAREHOUSE, electronic and electrical components, automotive parts, medical grade, fibers, plate grade |

| color | ALL |

| Shape | Rectangle |

| Brand Name | Yulon |

| Place of Origin | CN;GUA |

| Selling Units: | Single item |

| Single package size: | 70X40X15 cm |

| Single gross weight: | 5.000 kg |

Product Description

Product Name

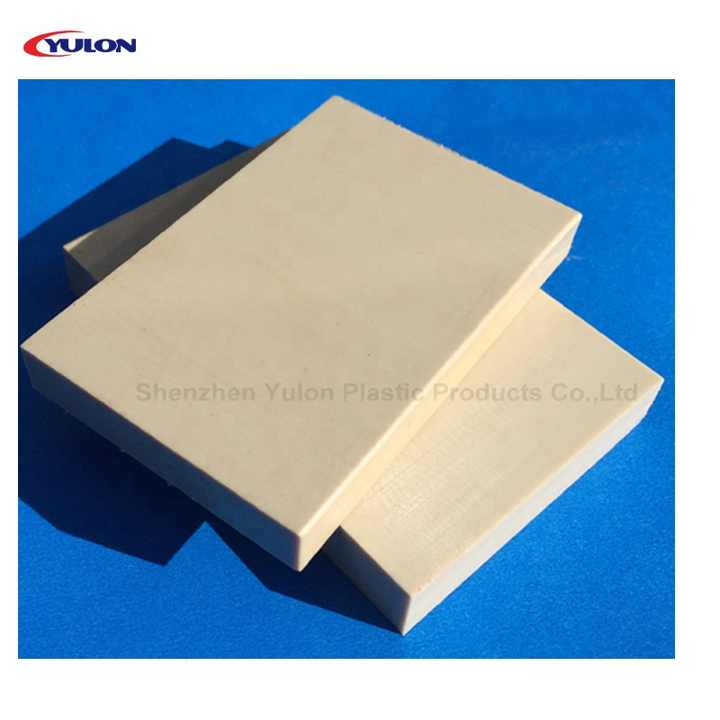

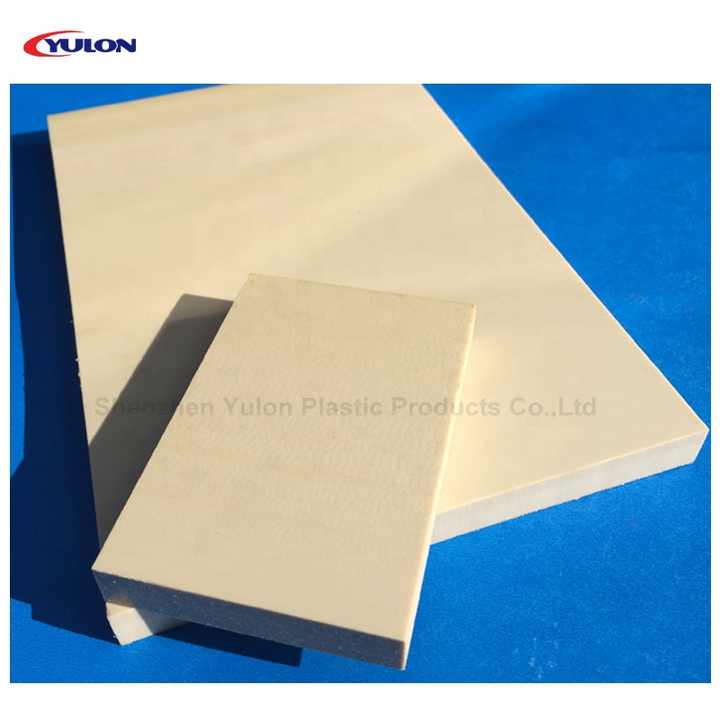

PEEK Plate

Product Size

W620 x L1250mm

Thickness

6mm,8mm,10mm,12mm,15mm,20mm,25mm,30mm ~ 70mm

Product Color

Natural/Black

Material

Polyether ether ketone

Application

Used for Aerospace,Medical,Valves,Seals etc.

Certification

SGS, RoHs , ISO

PEEK Plate

Product Size

W620 x L1250mm

Thickness

6mm,8mm,10mm,12mm,15mm,20mm,25mm,30mm ~ 70mm

Product Color

Natural/Black

Material

Polyether ether ketone

Application

Used for Aerospace,Medical,Valves,Seals etc.

Certification

SGS, RoHs , ISO

PEEK Product Information

PEEK offers a unique combination of high mechanical properties, temperature resistance (-50°C to +250°c),

and excellent chemical resistance, making it the most popular advanced plastics material. PEEK is also self extinguishing according to UL 94 VO.

PEEK offers a unique combination of high mechanical properties, temperature resistance (-50°C to +250°c),

and excellent chemical resistance, making it the most popular advanced plastics material. PEEK is also self extinguishing according to UL 94 VO.

Features And Benefits Of Natural PEEK Sheet

* Chemical resistant, hydrolysis resistant, autoclavable.

* Easy to machine and fabricate.

* Good mechanical properties at elevated temperatures.

* Strong and stiff.

* UL 94 V-0 flammability rating(0.059" thickness).

* Very low smoke and toxic gas emissions when exposed to flame.

* Chemical resistant, hydrolysis resistant, autoclavable.

* Easy to machine and fabricate.

* Good mechanical properties at elevated temperatures.

* Strong and stiff.

* UL 94 V-0 flammability rating(0.059" thickness).

* Very low smoke and toxic gas emissions when exposed to flame.

Cut-to-size Service:

FREE CUTTING - Please kindly tell us your cut to size board dimensions and qtys when you place order.

All offcuts can be supplied with your order

FREE CUTTING - Please kindly tell us your cut to size board dimensions and qtys when you place order.

All offcuts can be supplied with your order

Properties

Test Method

Unit

Data

Density

ISO 1183

g/cm³

1.32

Water absorption

ISO 62-1

%

0.11

Tensile strength Yield

ISO 527

Mpa

102

Elongation at Break

ISO 527

%

11

Elastic Bending Modulus

ISO 178

Mpa

3756

Impact Strength(notched)

ISO 179

KJ/M2

3.9

Hardness

ISO868

Shore D

90

Coeeficient of friction

ASTM D1894

-

0.34

Heat deflection temperature - HDT/A

ISO 75

℃

158

Heat deflection temperature - HDT/B

ISO 75

℃

240

service temperature-short term

/

℃

310

service temperature-long term

/

℃

-40~260

Thermal Conductivity

ISO 22007-4

W/(m.k)

0.25

Melting temperature

DIN EN ISO3146

℃

340

Surface Resistivity

IEC60093

Ohm (Ω)

≥1013

Dielectric strength

IEC60243-1

KV/mm

16

Dielectric Constant at 1MHz

IEC60250

-

3.2

Dielectric Loss Coefficient at 1MHz

IEC60250

-

0.003

Flammability

UL94

-

V0

Test Method

Unit

Data

Density

ISO 1183

g/cm³

1.32

Water absorption

ISO 62-1

%

0.11

Tensile strength Yield

ISO 527

Mpa

102

Elongation at Break

ISO 527

%

11

Elastic Bending Modulus

ISO 178

Mpa

3756

Impact Strength(notched)

ISO 179

KJ/M2

3.9

Hardness

ISO868

Shore D

90

Coeeficient of friction

ASTM D1894

-

0.34

Heat deflection temperature - HDT/A

ISO 75

℃

158

Heat deflection temperature - HDT/B

ISO 75

℃

240

service temperature-short term

/

℃

310

service temperature-long term

/

℃

-40~260

Thermal Conductivity

ISO 22007-4

W/(m.k)

0.25

Melting temperature

DIN EN ISO3146

℃

340

Surface Resistivity

IEC60093

Ohm (Ω)

≥1013

Dielectric strength

IEC60243-1

KV/mm

16

Dielectric Constant at 1MHz

IEC60250

-

3.2

Dielectric Loss Coefficient at 1MHz

IEC60250

-

0.003

Flammability

UL94

-

V0

Packing Details : Standard export pallets.

Lead Time : 3-15 working days after payment received.

Lead Time : 3-15 working days after payment received.

Q: Are you a factory or trading company?

A: We are a professional factory in China, with R&D department, whole production line,QC department, sales team and after-sales team.

A: We are a professional factory in China, with R&D department, whole production line,QC department, sales team and after-sales team.

Q: How about your lead time?

A: For samples, it could be 3-5 days to prepare them. For mass production, it may take7-20 days depending on your order qty and difficulty of product processing.

A: For samples, it could be 3-5 days to prepare them. For mass production, it may take7-20 days depending on your order qty and difficulty of product processing.

Q: What is your payment terms and how can i place an order?

A: We can receive payment via TT, TA etc, For mass production, 50% deposit to confirm the order,and 50%

payment to be paid after production finished. For samples, 100% payment to prepare the samples delivery.

A: We can receive payment via TT, TA etc, For mass production, 50% deposit to confirm the order,and 50%

payment to be paid after production finished. For samples, 100% payment to prepare the samples delivery.

machine parts uhmwpe ptfe pom nylon peek part cnc peek 1000

$40.5 ~ $42

Smart Device Industry Chain · Material · Rubber and Plastics

Shenzhen

Shenzhen  Authenticated

Authenticated100-499 EmployeesWholesale/Retail/New Retail