Product

Preview

Basic Info.Product Description

Basic Info.

| Place of Origin | Japan |

| color | natural color black |

| Shape | Plastic particles |

| Application | electronic and electrical components, optical grade, General grade, automotive parts, power tool accessories |

| Grade | hollow grade, hot melt grade, molding, calendering, demoulding grade |

| Feature | High flow, aging resistance, reinforced grade, Powder, ANTISTATIC, High Gloss |

| Brand Name | Polyplastics |

| Material name | BPT |

| Brand | Polyplastics |

| Model Number | 3116/733LD/2002 ED3002 |

| Color | Natural / Black |

| Certificates | COA/MSDS/TDS |

| Material shape | Particles |

| use | Engineering Components Automotive Applications |

| Place of Origin | Japan |

| Grade | injection molding arade |

| Product name | Polybutylene terephthalate |

| Selling Units: | Single item |

| Single package size: | 60X60X60 cm |

| Single gross weight: | 1.000 kg |

Product Description

Reminder : Price will be based on quotation's real-time update provided by sales person !!

1. Polybutylene terephthalate (PBT)

PBT can also be called thermoplastic polyester plastic. In order to be suitable for use by different processing industries, additives are generally added or mixed with other plastics. Different specifications of products can be manufactured according to the different proportions of additives. Because PBT has heat resistance, weather resistance, chemical resistance, good electrical properties, low water absorption, and good gloss, it is widely used in electronic appliances, auto parts, machinery, household products, etc., and PBT products are collectively called the five major general-purpose engineering plastics together with PPE, PC, POM, PA, etc.

2. Advantages

Excellent mechanical properties, especially high rigidity and hardness. Good heat resistance, heat deformation temperature can reach above 180℃. Good surface gloss, especially suitable for spray-free electronic and electrical products. Faster crystallization speed, good fluidity, excellent formability. Good thermal stability, especially low thermal expansion rate and dimensional shrinkage rate. Good resistance to chemicals, solvents, and weathering. High dielectric strength, good electrical properties. Low hygroscopicity, minimal effect on electrical and dimensional stability.

3. Disadvantages:

The molecule contains ester bonds, which will decompose under the action of strong acids, strong bases and water vapor. The material is more sensitive to gaps and is brittle.

4. Application scenarios

The application-related industries include automobiles, electronics/electrical appliances, and machinery:

Connectors

The connector is a bridge between signals and is an indispensable component for transmitting electronic signals and power connections. The balanced physical properties and price of PBT meet the needs of connectors. PBT is usually mixed with 30% glass fiber as a connector. PBT is widely used due to its mechanical properties, solvent resistance, good forming processability and low price. PBT cannot be used in SMT connect

PBT can also be called thermoplastic polyester plastic. In order to be suitable for use by different processing industries, additives are generally added or mixed with other plastics. Different specifications of products can be manufactured according to the different proportions of additives. Because PBT has heat resistance, weather resistance, chemical resistance, good electrical properties, low water absorption, and good gloss, it is widely used in electronic appliances, auto parts, machinery, household products, etc., and PBT products are collectively called the five major general-purpose engineering plastics together with PPE, PC, POM, PA, etc.

2. Advantages

Excellent mechanical properties, especially high rigidity and hardness. Good heat resistance, heat deformation temperature can reach above 180℃. Good surface gloss, especially suitable for spray-free electronic and electrical products. Faster crystallization speed, good fluidity, excellent formability. Good thermal stability, especially low thermal expansion rate and dimensional shrinkage rate. Good resistance to chemicals, solvents, and weathering. High dielectric strength, good electrical properties. Low hygroscopicity, minimal effect on electrical and dimensional stability.

3. Disadvantages:

The molecule contains ester bonds, which will decompose under the action of strong acids, strong bases and water vapor. The material is more sensitive to gaps and is brittle.

4. Application scenarios

The application-related industries include automobiles, electronics/electrical appliances, and machinery:

Connectors

The connector is a bridge between signals and is an indispensable component for transmitting electronic signals and power connections. The balanced physical properties and price of PBT meet the needs of connectors. PBT is usually mixed with 30% glass fiber as a connector. PBT is widely used due to its mechanical properties, solvent resistance, good forming processability and low price. PBT cannot be used in SMT connect

Shanghai Fulexing Import and Export Co., Ltd. specializes in the import and export of plastic raw materials. With its professional

elite team, high-quality and enthusiastic service, and systematic and standardized operating procedures, the company actively

expands the market, widely establishes cooperation platforms, and wins customer recognition. At present, the company has business,

customer service, operation, warehousing, customs declaration, inspection, transportation, finance, administration and other

departments. All departments work together and perform their duties to provide customers with faster and better services. Shanghai

Fulexing Co., Ltd. is a company whose main business is plastic raw material export business, agency customs declaration and

inspection, and business consulting. It has extensive customer resources and sales networks in Northeast, North China, Central

China, and Northwest China. The company takes "integrity, accuracy, and efficiency" as its concept and "mutual benefit and

win-win" as its purpose, providing customers with "one-stop" services such as high-quality plastic raw material import and export,

logistics services, etc., and planning faster, more convenient, and cheaper solutions for you. Because our expertise can shorten

the distance between you and the world, bring you closer to the world, and accelerate your pace towards the world trade stage.

elite team, high-quality and enthusiastic service, and systematic and standardized operating procedures, the company actively

expands the market, widely establishes cooperation platforms, and wins customer recognition. At present, the company has business,

customer service, operation, warehousing, customs declaration, inspection, transportation, finance, administration and other

departments. All departments work together and perform their duties to provide customers with faster and better services. Shanghai

Fulexing Co., Ltd. is a company whose main business is plastic raw material export business, agency customs declaration and

inspection, and business consulting. It has extensive customer resources and sales networks in Northeast, North China, Central

China, and Northwest China. The company takes "integrity, accuracy, and efficiency" as its concept and "mutual benefit and

win-win" as its purpose, providing customers with "one-stop" services such as high-quality plastic raw material import and export,

logistics services, etc., and planning faster, more convenient, and cheaper solutions for you. Because our expertise can shorten

the distance between you and the world, bring you closer to the world, and accelerate your pace towards the world trade stage.

supply

POM

PA66

PC

PC/ABS

PA6

ABS

TPE

PEEK

PP

PPS

PET

TPU

PA12

POE

EVA

PP0

ASA

LCP

PMMA

POM

PA66

PC

PC/ABS

PA6

ABS

TPE

PEEK

PP

PPS

PET

TPU

PA12

POE

EVA

PP0

ASA

LCP

PMMA

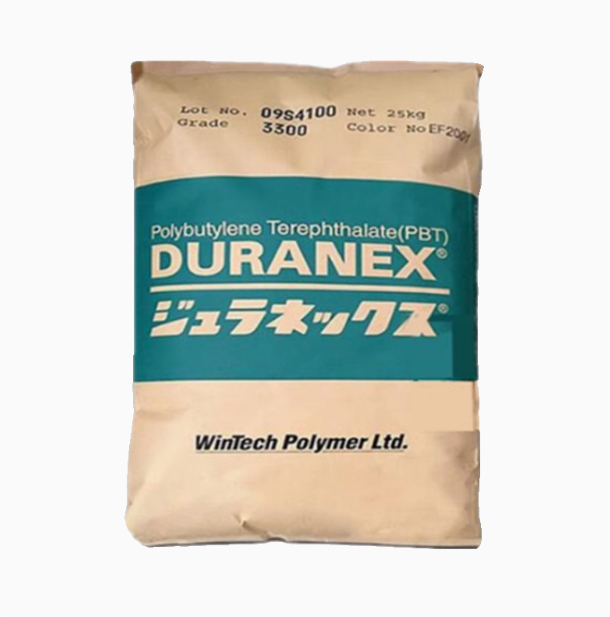

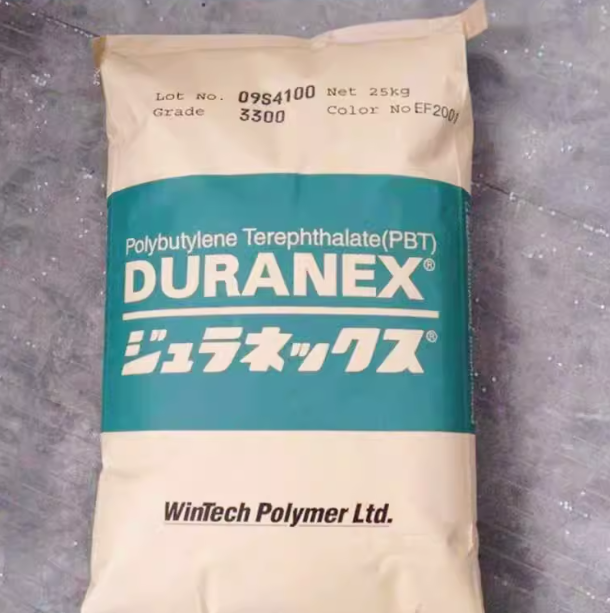

DURANEX/PBT Japan Polyplastics3116/733LD/2002 ED3002 /High gloss, impact resistance, high temperature resistance

$1.5 ~ $2

Smart Device Industry Chain · Material · Rubber and Plastics

global.BrandPolyplastics

Shanghai

Shanghai  Authenticated

Authenticated50-99 EmployeesWholesale/Retail/New Retail